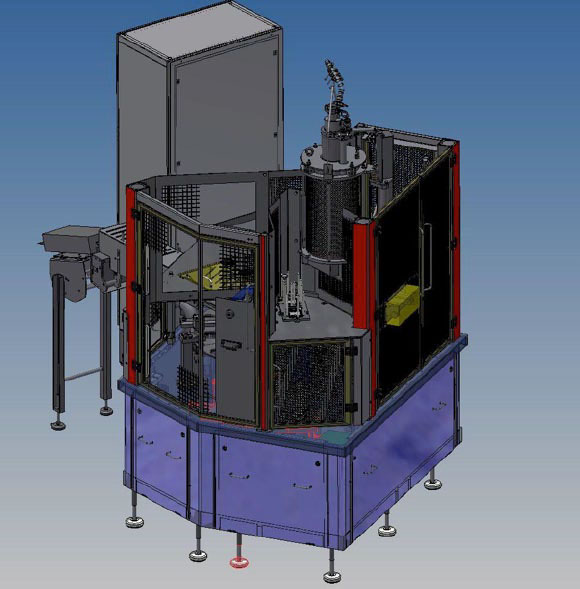

Plan a trip to Germany to see Waldner DOSOMATS

See the value and performance only a DOSOMAT can deliver. There is always a steady

stream of DOSOMAT filling and sealing machines on the production floor at the Waldner

factory in scenic Wangen, Germany. The following machines are currently available for

demonstration through March 2016!

Contact Julian Stauffer to learn about these models and upcoming production schedules.

info@ptipacktech.com or j.stauffer@ptiusa.com, 914.337.2005.

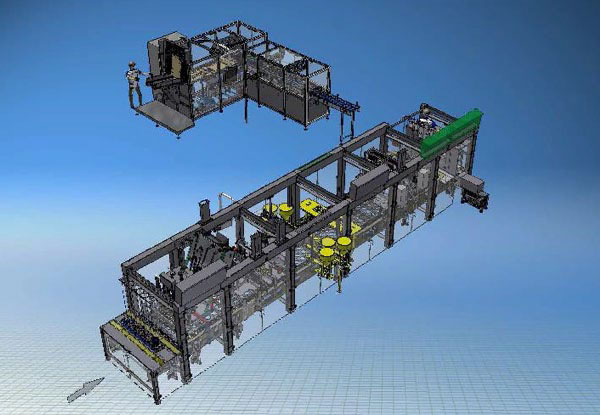

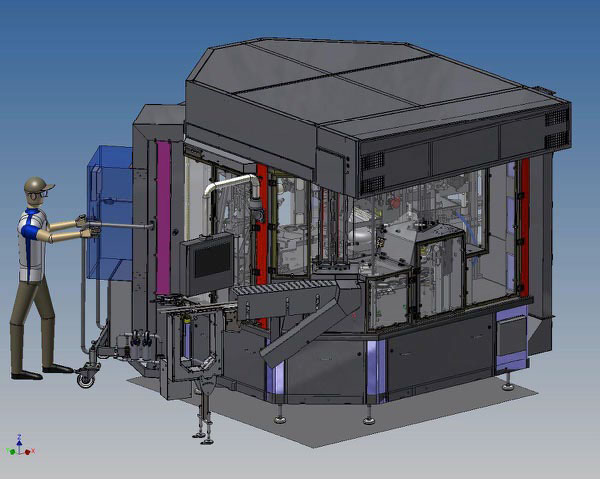

DOSOMAT 20.5 Pouch Machine for Pet Food

Compact inline machine for filling & sealing pet food in stand-up retort pouches

- Capacity: up to 200 pouches per minute

- 3 different pouch formats

- Single shot piston dosing system

- Closure: Special ultrasonic sealing and cosmetic heat sealing

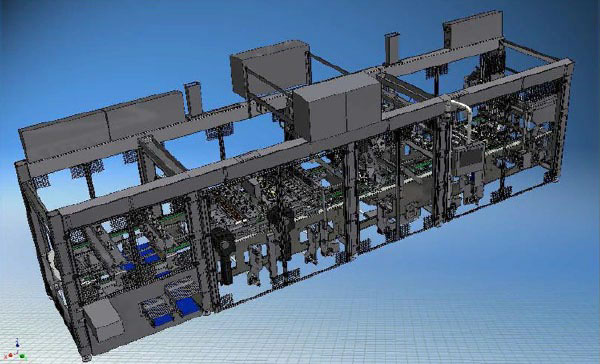

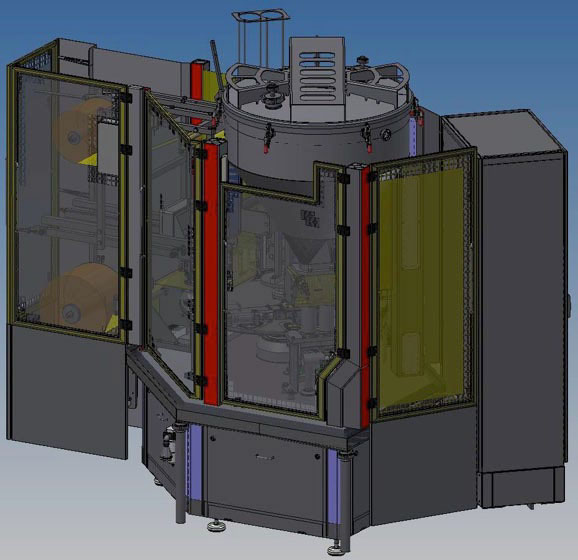

DOSOMAT 20.6 – Complete Packaging

Line for Hummus

Inline machine for filling and sealing Hummus in plastic cups, with a Wrap-Around-Packer for end of line packaging into cartons

- Capacity: up to 220 pouches per minute

- 5 dosing systems: main dosing system for Hummus, topping filler and oil filler,

“decoration” filler for powder and free space for vibration filler

- Complete dosing systems and product hopper in CIP design

- Closure: Sealing film from roll stock and snap-on lid

- WALDNER Wrap-Around-Packer for packing of cups into cartons with several layers

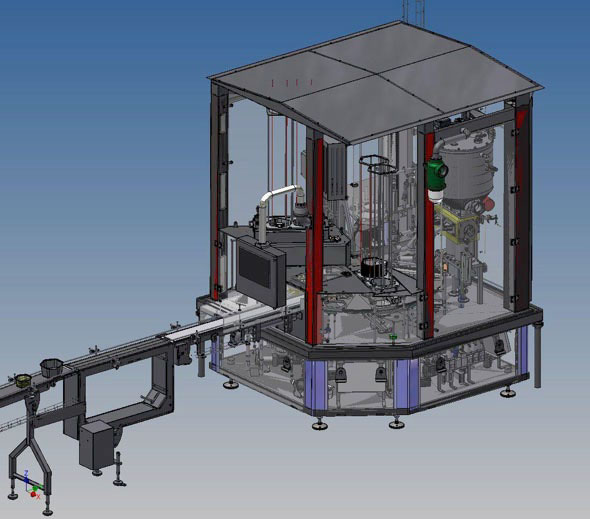

DOSOMAT 12.2 ESL with Package Sterilization for Hummus

Rotary machine for filling & sealing Hummus, with innovative “Pulsed Light” cup sterilization and UV-irradiation of sealing film

- Capacity: up to 25-30 cups/minute with vacuum; up 60 cups/minute with gas flushing

- Cup sterilization via Claranor® “Pulsed Light”

- Main dosing station for filling Hummus

- Removable pre and post-dosing stations for toppings or herbs

- CIP/SIP cleaning of main, pre and post-dosing stations

- UV-irradiation of sealing film

- Heat sealing from roll stock with vacuum and gas injection or flushing

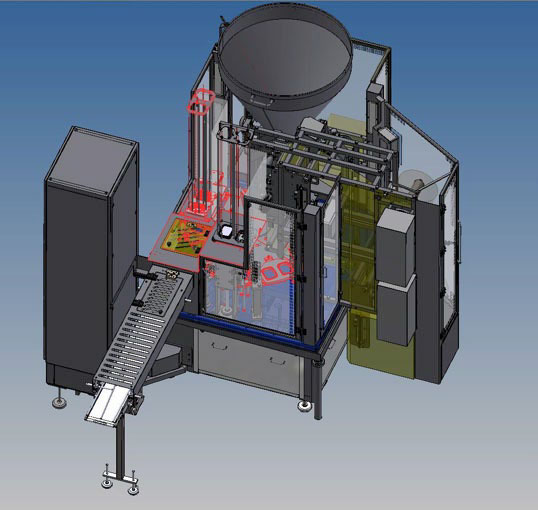

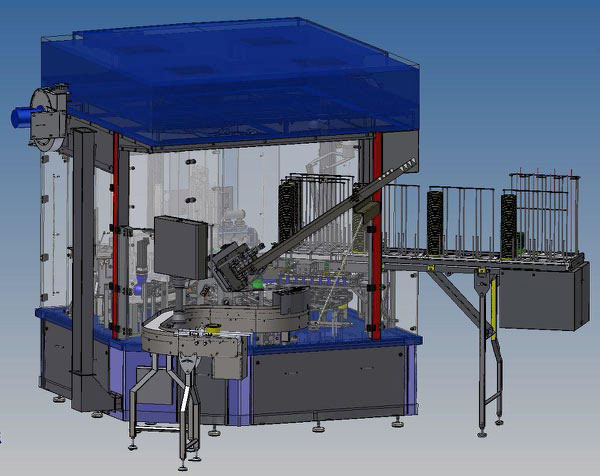

DOSOMAT 12.4 – Dosing with Multihead Weigher

Rotary State-of-the art rotary machine for filling Mozzarella balls in different cup formats

- Capacity: up to 125 cups per minute

- Dosing of Mozzarella via Multihead Weigher

- Post dosing station for water/brine using a timed liquid fill

- CIP cleaning

- Heat sealing from roll stock, with printed film registration

DOSOMAT 2.2 – Rotary Machine for Dairy Products

- Capacity: up to 60 cups per minute

- Piston dosing system for cream cheese with CIP-cleaning

- Closure: Heat sealing of pre-cut aluminum lids and snap-on lidding

DOSOMAT 2.2 – Rotary Machine for Delicatessen Products

- Capacity: up to 85 cups per minute

- 2 cup formats in quick change system

- Filling of delicatessen salads via piston dosing system with special tappet valves

- CIP cleaning of dosing system and product hopper

- Sealing from roll stock and snap-on lid

- Format trolley for simple transport of format parts

DOSOMAT 2.2 – Rotary Pet Food Machine with Aluminum Cup Sealing

- Capacity: up to 85 cups per minute

- Piston dosing system with special rotary cutter bolts for large meat pieces

- Compensation cylinder with inlet and outlet nozzle for the product

- Level control inside the compensation cylinder via linear potentiometer

- Sealing: Spot sealing and innovative WALDNER “Alu-Alu sealing” system

DOSOMAT 1.2 – Compact and Flexible Rotary Machine

- Capacity: up to 85 cups per minute

- Includes 2 format parts in quick change design and format trolley

- Removable filler: piston dosing system with special rotary cutter

- Sealing from roll stock including printed film registration